Robotic bending cells: what they are and how they work

Automation, precision and productivity: how automated bending cells are transforming the bending process in industrial carpentry

In metal carpentry, automation is now one of the most effective tools to improve production quality, increase safety and reduce processing times. Among the most advanced solutions that are revolutionizing production departments are robotic bending cells, intelligent systems designed to automate sheet bending operations and perform them in a precise, repeatable and continuous way.

Before the introduction of automated bending cells, sheet metal processing was a process that depended heavily on the manual skills and experience of the operators. Each step – from positioning to bending, right through to quality control – required the utmost attention and could be subject to human errors and production process slowdowns. The introduction of robotic cells has helped to speed up and improve processing processes, helping companies to achieve new quality standards and increase production considerably.

Let’s see in more detail what a robotic bending cell is, how it works and what benefits it can provide to companies in the sector.

What is a robotic bending cell

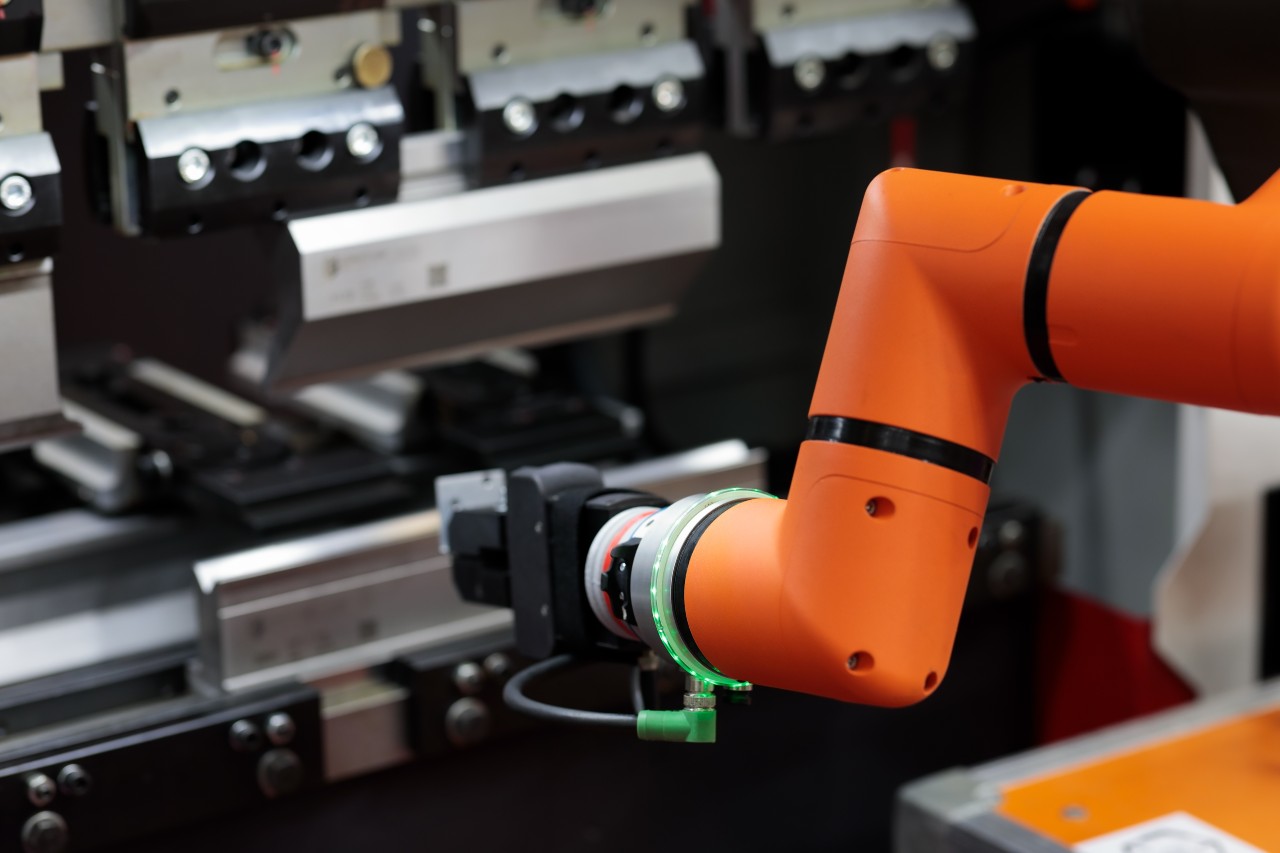

A robotic bending cell is an integrated system that automates the sheet bending process, combining mechanical precision, digital control and robotic handling. These cells represent the technological evolution of traditional bending lines and are designed to guarantee high productivity, constant quality and operational safety, even in continuous working conditions.

The heart of the bending system is represented by a CNC bending press, programmable in every detail to perform folds with maximum precision and repeatability. In support of the bending machine, one or more anthropomorphic robots handle the parts during the whole production cycle: they take the raw sheets from the loading areas, they place them on the bending tool with millimetre precision and transfer the finished parts to the discharge stations or further processing steps.

To complete the bending cell, other key devices come into play, such as:

- artificial vision systems that enable the robot to recognise the position and orientation of workpieces, automatically correcting any misalignment;

- sensors and encoders: they constantly monitor the execution of the fold, ensuring that the dimensional tolerances are respected;

- automatic loading/unloading systems: they feed the cell continuously, reducing downtime and optimising the production cycle.

In the most advanced models we also find automatic tool change systems, ideal for quick transitions between different types of bending. These solutions fit perfectly into the paradigm of Industry 4.0, thanks to the integration with management software that allows real-time control of the production cycle, data collection and traceability of each piece.

How a robotic bending system works

The operation of a robotic bending system is a concrete example of how industrial robotics can make more efficient, safe and repeatable traditional manual processes such as sheet bending. The main operational phases include:

- automatic loading of the workpiece: the robot picks up the sheet from a pallet or from a belt, using clamps or suction cups. In some configurations, it is driven by a vision system which recognizes the position and orientation of the workpiece;

- positioning on the press: the workpiece is precisely positioned on the CNC bending machine and held in position during the operation. Some systems use rotary grippers or multiple arms to perform multiple folds with a single grip;

- bending: the press performs the machining according to the loaded program, with each phase controlled by sensors for compliance with tolerances;

- unloading the finished part: the robot picks up the workpiece and places it in a special area or transfers it to a subsequent line. In some cases, it can perform rotations for additional folds on other axes;

- integrated quality control: the most advanced cells include lasers, taps or vision systems for in-line quality control, verifying the conformity of the parts produced;

- cycle repetition: the process is repeated continuously and automatically. In case of anomalies, the system will shut down autonomously by reporting the error.

The new generation models also include automatic tool change, drastically reducing setup times and increasing productivity in complex machining.

The advantages of using robotic bending cells

Integrating a robotic cell in the bending department means guaranteeing several concrete, measurable benefits that represent a competitive advantage for all companies that aim to optimize efficiency, quality and safety. The main advantages include:

- repeatability and precision: each bending is carried out with the utmost precision, eliminating human errors and waste thanks to numerical control and robotic handling;

- increased productivity: the cells work without breaks, even during night shifts or on weekends, with a significant increase in production capacity;

- safety of personnel: by automating the most risky steps, the risk of accidents for operators is greatly reduced;

- production flexibility: the robotic bending islands can be quickly reconfigured to adapt to different part geometries and allow a lean and efficient management even of small batches or just-in-time orders;

- data traceability and control: each step is monitored and recorded, offering complete traceability, useful for certifications, quality and continuous improvement;

- waste reduction: Thanks to the precision of numerical control and consistency of automated operations, robotic cells significantly reduce production waste, contributing to a more sustainable and cost-effective process.

Ferrero Industrial stands for quality and innovation in metal carpentry. Thanks to technologically advanced machines, which includes robotic cells for sheet bending able to guarantee high quality standards and competitive delivery times, The company is a reference point for the manufacture of custom-made metal components, including aerial lift parts, telehandlers equipment and industrial vehicle components.

Our strength is the customization of the project: we follow every customer from prototyping to series production, offering effective, fast and customized solutions.

Contact us for more information or to request a dedicated consultation!