How to choose aerial work platforms equipment

Complete guide to buying aerial work platforms equipment

Aerial platforms are indispensable machines in many industrial sectors to carry out work in height. Thanks to their particular structure, they can reach great heights in a safe and efficient way, allowing operators to work even in confined spaces or in places otherwise difficult to access. Choosing the right components for aerial work platforms is an important aspect to allow an optimal functioning of the machines, increase productivity and, at the same time, ensure the safety of operators. Every component, be it chassis, work platforms or other structural parts, contributes to the proper functioning of the platform and to the protection of operators during use.

Low quality or unsuitable components can increase the risk of damages, malfunctions or accidents, compromising work efficiency. Therefore, it is crucial to choose high-quality components, designed and built to withstand the stresses of the work environment and ensure reliable performance over time. Investing in quality components means improving the safety and efficiency of operations, minimizing downtime and ensuring higher overall productivity. In addition, the choice of components can also affect long-term maintenance costs, as quality components tend to be more durable and require less repair and replacement.

Let’s see together what are the essential components of aerial works platforms and some advice on how to choose the most suitable ones for each application.

Essential aerial work platforms components

The structure of an aerial platform is composed of several elements, which are essential to ensure a safe and efficient operation of the machine. While all platforms differ in height, maximum lifting weight and mobility, they have some essential components in common, including:

- motor, which provides the necessary power for lifting and movement. Generally, these are internal combustion or electric engines, depending on the type of platform. The motor converts energy into motion, allowing the platform to lift, lower and move sideways;

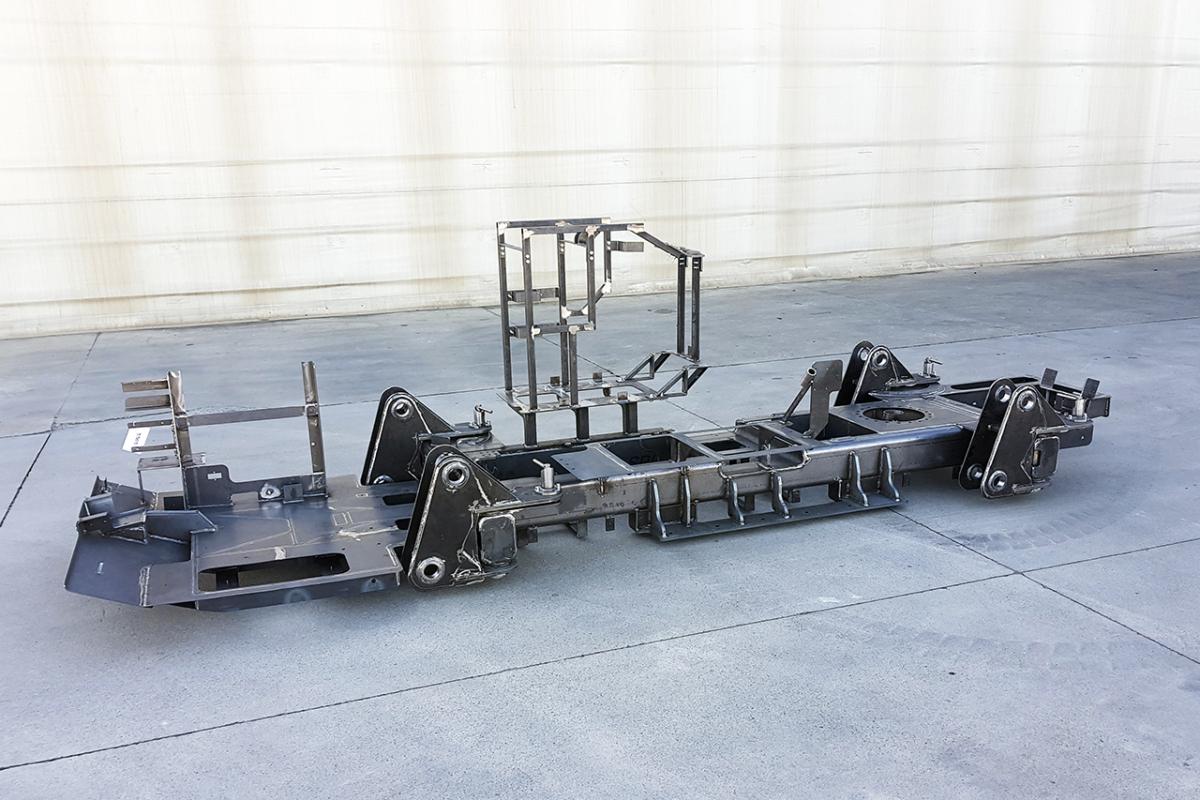

- chassis, also known as base or wagon base, which constitutes the basic support structure of the platform. Its main function is to ensure the stability of the machine and the extensible part, and can be self-propelled or towed. Its construction can vary depending on the type of platform, with specific features such as an auxiliary steel chassis for trucks or four mobile wheels for self-propelled telescopic or articulated platforms. The chassis also determines the speed of movement, the ability to steer and the type of slope on which the platform can operate;

- stabilizers, that is components mounted on the frame that ensure the stability of the platform during work. Used especially for truck mounted platforms, they allow to distribute the load evenly, extending the support surface. These components, similar to hydraulic cylinders, prevent dangerous overturns and oscillations while keeping the chassis level;

- extensible structure or boom lift, which is the part that allows the platform to reach the necessary height. Fixed to the chassis, it can be telescopic, articulated or scissor. This component allows the vertical movement of the platform and, in some cases, also rotary movements;

- hydraulic system, consisting of pumps, valves, hydraulic cylinders and hoses, designed to withstand high pressures during work. To ensure maximum safety, the platforms are equipped with indicators to monitor the pressures and lock valves to avoid sudden movements that could damage the machine;

- platform, also known as “basket”, is the mobile part where operators work. Connected to the extensible structure, it allows workers to perform repair, construction or inspection work in total safety. Made of lightweight and durable materials, it is usually equipped with a rotation system and a protected access for the operator.

Each component plays a key role in ensuring the proper operation and safety of aerial platforms, allowing you to perform works efficiently and safely at high heights.

Factors to consider when choosing components

When choosing the most suitable aerial work platform components, it is important to consider several aspects that can directly affect the efficiency and proper operation of the machines. First of all, the reliability and safety of components are crucial: opting for high-quality, safety-compliant components can increase productivity and significantly reduce the risk of accidents. Compatibility with the specific platform type and model is also essential to ensure proper installation and optimal operation.

When choosing the most suitable aerial work platform components, it is important to consider several aspects that can directly affect the efficiency and proper operation of the machines. First of all, the reliability and safety of components are crucial: opting for high-quality, safety-compliant components can increase productivity and significantly reduce the risk of accidents. Compatibility with the specific platform type and model is also essential to ensure proper installation and optimal operation.

Components must also be designed to withstand wear and stress in the working environment, ensuring a long service life. To this end, it is important to choose robust and durable materials, such as stainless steel or composite materials that offer high performance and corrosion and wear resistance. Ease of maintenance is another aspect to consider: components that allow easy and quick maintenance can help to reduce the downtime of the aerial platform and maintain high performance of the device. Finally, it is essential to verify that components have been subjected to rigorous safety and quality tests and that they have the necessary certifications to ensure compliance with current regulations. Carefully considering these factors when choosing components for aerial platforms is essential to ensure safe and efficient operation of the work equipment and maximize productivity and durability.

Aerial platforms baskets: what characteristics should they have?

Platform baskets are essential components for safe working at height and should be designed to provide ample space and comfort for operators, allowing them to move freely inside and easily access the tools and materials needed to do the job. Baskets must be equipped with strong railings to ensure the protection of employees and prevent the risk of falls during use. In addition, the loading capacity of the basket must be adapted to the specific needs of the work, ensuring that it can safely support the weight of operators and tools.

Platform baskets are essential components for safe working at height and should be designed to provide ample space and comfort for operators, allowing them to move freely inside and easily access the tools and materials needed to do the job. Baskets must be equipped with strong railings to ensure the protection of employees and prevent the risk of falls during use. In addition, the loading capacity of the basket must be adapted to the specific needs of the work, ensuring that it can safely support the weight of operators and tools.

Basket stability is another crucial aspect to consider: it should be designed to maintain a stable position even in the presence of wind or sudden movements of the aerial platform. For this reason, it is also important to evaluate the strength and durability of materials used for the construction of the basket, preferring resistant materials, such as steel, that ensure a long life and greater protection of operators. Finally, it is essential to choose baskets that comply with safety regulations and that are equipped with certifications that ensure their quality. Paying attention to these aspects will help you to select the most suitable baskets for each application and the specific needs of the work environment.

Aerial platform boom lift: types and characteristics

In order to choose the aerial platform boom lift that best suits the type of application and work to be done, it is essential to understand the different types available and their specific characteristics. There are mainly three types of boom lifts used in aerial platforms:

- telescopic boom lift, which allows you to extend the platform upwards, offering greater reach without the need to move the base of the platform. This type of boom is particularly suitable for work in height on vertical structures such as buildings or towers, where a large coverage area is required without the need for frequent movement;

- articulated boom lift, composed of several sections connected by joints that allow angular movements. This type of arm offers greater flexibility and versatility, allowing operators to reach hard-to-reach positions with other types of arms. It is ideal for work on areas with obstacles or in particularly narrow spaces, where a wide range of movements is required;

- scissor boom lift, which can extend and retract vertically, allowing operators to lift and lower the aerial platform without extending the coverage area horizontally. This type of boom is particularly suitable for work on flat ground or for vertical lifting operations, such as maintenance of electrical systems or for pruning operations.

To choose the most suitable type of boom lift for each application and work in height, it is important to first assess the specific needs of the work, including the height achievable, the required capacity and the presence of any obstacles or spatial constraints. In addition, it is important to consider the stability and safety of the arm, making sure it is able to withstand the weight of operators and tools safely and efficiently. Finally, it is advisable to opt for arms for aerial platforms equipped with advanced safety systems, such as anti-collision sensors or automatic locking devices, to minimize the risk of workplace accidents.

Ferrero Industrial offers a wide range of aerial work platforms equipment characterized by high standards of safety, quality and resistance. All components are made of carefully selected materials and are designed to guarantee maximum stability and safety during use, ensuring reliable and long-lasting performance. From structural carpentry to mechanical components, to plates and baskets: all products can be made to measure, according to the specific needs of each customer and the type of application for which they are intended.

For more information on components for aerial platforms or other types of welded products proposed by Ferrero Industrial, contact us!