How are metal profiles produced?

From the raw material to the finished product: everything you need to know about the production of metal profiles

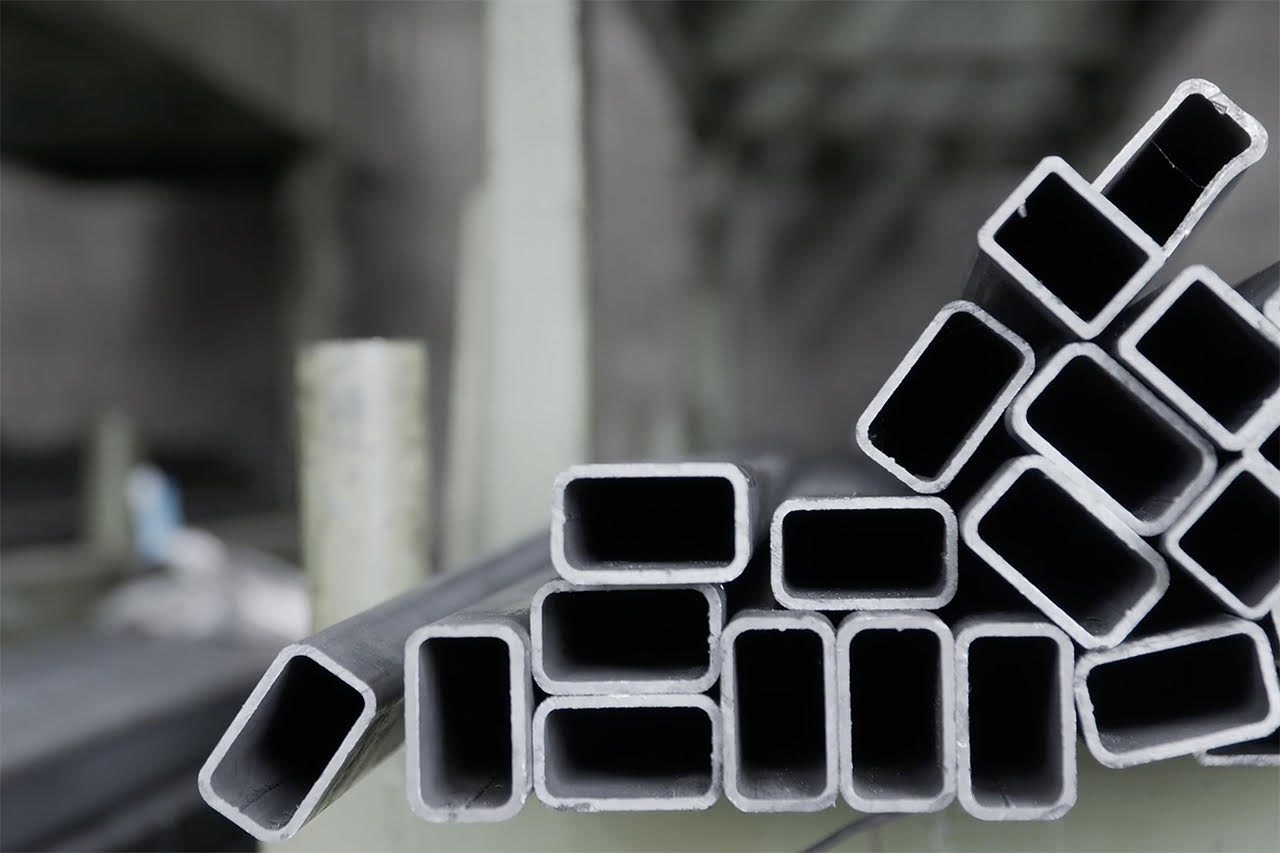

Metal profiles are constant cross-sectional metal bars, available in a wide range of standardized shapes and sizes, offering an optimal combination of mechanical strength, lightness and versatility.

In the field of metal carpentry, they play a fundamental role in the construction of load-bearing structures, beams, columns and a myriad of other structural components, but also in the construction of different types of machines and vehicles. Due to their ability to withstand high loads, resist mechanical stress and ensure the stability of structures, they are often used as load-bearing frames for buildings, bridges, industrial plants and many other constructions.

They can be cut, welded, drilled and assembled by bolting or other connection systems, allowing the construction of complex structures in a short time and with high precision. In addition, the durability and corrosion resistance of the profiles ensure a long life over time, reducing maintenance costs and ensuring the safety of the constructions.

Let us look in more detail at what metal profiles are, what they are used for and how they are produced.

What are metal profiles and what are they used for?

Metal profiles are structural elements widely used in modern architecture, characterized by a constant cross-section along their entire length. These metal components are generally obtained by hot or cold rolling, drawing or extrusion and are characterized by their strength and versatility, making them indispensable in a wide range of applications.

The versatility of metal profiles is evident in the wide range of shapes and sizes available, ranging from simple L, U or T profiles to profiles with complex hollow or tubular sections. This variety allows you to choose the optimal solution for each specific need, optimizing the distribution of stresses and ensuring maximum structural efficiency. In addition, the choice of materials such as carbon steel, stainless steel, aluminum or other metal alloys allows profiles to be adapted to specific conditions of use, taking into account factors such as corrosion resistance, thermal or electrical conductivity and weight.

In addition to their structural role, metal profiles are also used in other applications such as the manufacture of frames and components for machines, guides for transport systems and much more. Their ease of processing and assembly, combined with the possibility of being welded, bolted or joined by other connection systems, makes them adaptable to the most diverse design requirements.

The different types of metal profiles

Metal profiles can be made with different shapes and sizes depending on the type of use and sector to which they are intended. Standard profiles generally include:

- L-shaped profiles (or corner profiles), characterized by an “L” shaped section, which are widely used for the realization of corners, frames, reinforcements and light structures;

- U-shaped profiles with a “U” shape, which offer greater resistance to bending than L-shaped sections and are often used for the construction of beams, columns and guides;

- T-shaped profiles: their “T” shaped section makes them ideal for the construction of beams, slabs, frames and other structures that require good resistance to bending and torsion;

- H-shapes profiles, also known as “HEA beams” or “IPE beams”, have an “H” shaped section and are widely used in the construction industry and in metal joinery for the realization of load bearing structures, columns and beams;

- tubular profiles: circular, square or rectangular in shape, they offer high torsional strength and are used in applications such as lightweight structures, frames, plumbing and mechanical installations;

- flat profiles, consisting of flat sheets of varying thickness, are used for the production of coatings, panels, connecting elements and other applications requiring a flat surface.

In addition to standard profiles, it is possible to produce custom-made metal profiles with shapes and dimensions customized according to the specific requirements of the project. This solution offers greater design flexibility and allows you to optimize material utilization, reducing waste and production costs. Custom-made profiles are used in sectors such as automotive, aerospace, mechanical engineering and all those applications that require specific solutions not available among standard profiles.

The choice of the most suitable metal profile type depends on many factors, including the applied load, environmental conditions and aesthetic requirements. A careful evaluation of these aspects, combined with the advice of experts in the field, can help to identify the optimal solution for each project, ensuring maximum efficiency, safety and durability of the structures.

Production techniques for metal profiles

The production of metal profiles is a complex process, which can be carried out using different techniques, each of which offers specific advantages in terms of dimensional accuracy, mechanical properties and adaptability to different shapes and sizes. The main production techniques include:

- hot rolling: this process involves heating the metal at high temperatures, above its recrystallization temperature (usually between 1000 and 1300°C), and then passing it through a series of rollers which deform it plastically, Giving it the desired shape. Hot rolling is particularly suitable for the production of large-sized and thick profiles, guaranteeing high productivity and good control of mechanical properties;

- cold rolling: similar to hot rolling, this process is carried out at room temperature or slightly higher, allowing to obtain profiles with tighter dimensional tolerances and a better surface finish. Cold rolling is ideal for the production of small-sized and thin-walled sections, often used for applications requiring high precision and aesthetic quality;

- extrusion: in this process, a heated metal ingot is forced through a matrix, taking the form of the cross-section of the matrix itself. Extrusion allows profiles with complex geometries and internal cavities, offering great design flexibility. Particularly suitable for the production of aluminum and other non-ferrous alloy profiles;

- drawing: this technique involves the passage of a wire or bar through a die, a matrix with a hole smaller than the initial section of the material. Drawing allows to obtain profiles with high dimensional accuracy and surface finish, but is limited to relatively simple shapes and small dimensions.

Again, the choice of production technique depends on several aspects, including the type of metal, the shape and size of the desired profile, the required mechanical properties and the production volumes. Often, different techniques are combined to achieve the final result, for example hot rolling followed by cold drawing to improve dimensional accuracy.

Main usage areas for metal profiles

As we have seen, thanks to their versatility and excellent mechanical properties, metal profiles are used in a wide range of sectors and can be used for various industrial and civil applications.

In the construction industry and metal carpentry are essential elements for the realization of load-bearing structures, beams and columns. Their strength, lightness and ease of assembly make them ideal for the construction of buildings, bridges and industrial warehouses, guaranteeing safety and durability over time.

Thanks to their special characteristics, they are also often used for windows, doors and cladding, combining functionality and aesthetics and offering customized solutions for every architectural project.

In the mechanical industry, profiles are mainly used for the production of machinery and equipment, but also for the manufacture of components of different types, such as industrial vehicles parts or for car carrier trailer parts. Their lightness and strength improve the energy efficiency and safety of vehicles, reducing overall weight and increasing shock absorption capacity.

In the manufacturing industry, metal sections are used instead in the construction of machinery, plant, industrial shelving and transport systems, thanks to their ability to withstand high mechanical stress, vibration and loads, Ensuring the durability and reliability of structures even in harsh working environments. Their versatility allows to create modular structures adaptable to different production needs, allowing also easy reconfiguration of the plants in case of modifications or extensions.