Custom metal fabrication: from drawing to realization

Customized solutions for every need: the characteristics and advantages of custom-made metal fabrication

Custom metal fabrication is a crucial sector in modern industry, combining craftsmanship with technological innovation. This is a process that starts from detailed and customized design, until the final realization of the metal product. Custom metal carpentry can be applied in a variety of sectors, such as construction, for example steel scaffolding and roofing, or manufacturing industry, for the production of customized components, machinery and equipment. It can also be used in areas such as civil and industrial infrastructure, energy plant support structures and even in the construction of platforms or supports for advanced technologies.

Thanks to the use of resistant and durable materials such as stainless steel, aluminum and iron, metal carpentry products allow you to optimally meet the requirements of strength, aesthetics and functionality required by various sectors, ensuring solutions that last over time and that perfectly fit the environment in which they are inserted.

Let’s take a closer look at each stage of custom metal fabrication, and what advantages can be provided by a customized design.

What is custom-made metal fabrication

In general, metal fabrication can be defined as the set of techniques and operations which allow to work metal to create structures and industrial and civil components. When we talk about custom-made metal carpentry, we refer in particular to the manufacture of metal products designed specifically to meet unique requirements.

In general, metal fabrication can be defined as the set of techniques and operations which allow to work metal to create structures and industrial and civil components. When we talk about custom-made metal carpentry, we refer in particular to the manufacture of metal products designed specifically to meet unique requirements.

The added value of this process is customization: each product is made on the basis of technical specifications provided by customers, with a level of precision that meets high standards. To rely on a company with long experience in the sector, which is able to create tailor-made solutions – such as Ferrero Industrial – means being able to obtain unique, robust and durable products that perfectly adapt to the specific needs of each project.

Design of custom metal carpentry

Design is an essential step in custom-made metal carpentry: it allows you to avoid errors, optimize resources and ensure that every detail is realized exactly as requested by the customer. This process involves several steps:

- customer brief and collection of requirements: the first step is to meet with customers in order to understand their specific requests. At this stage, the technical, aesthetic and functional requirements of the project are defined;

- concept development: after gathering all the information, the first technical drawings and 3D models are created. This step is fundamental to create a simulation of the final product and make any adjustments before going into production;

- detailed technical design: once the concept has been approved, a complete technical design is developed, taking into account materials, dimensions, tolerances and assembly specifications;

- structural analysis and engineering checks: this is important to ensure that all safety regulations and standards are met.

Metal carpentry production: what is it?

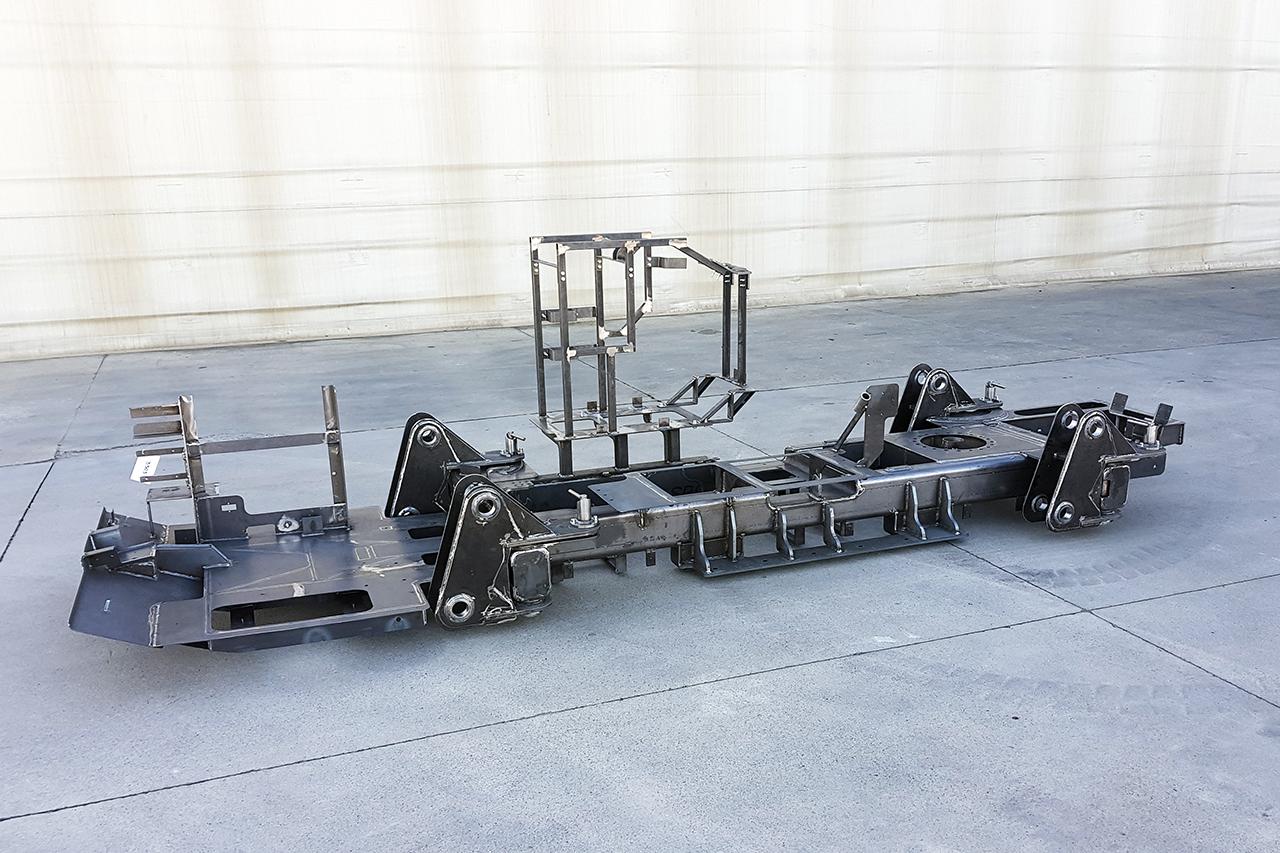

Once the design phase is completed, the actual production of metal carpentry takes place, a process which requires specialized skills and precision machinery. Each component is custom-made and with specific production technologies, ensuring a perfect match with the technical specifications of the project. This phase is divided into several steps:

- material cutting: depending on the project requirements, laser cutting is used to achieve maximum precision for complex components, plasma cutting for thicker and more resistant metals, band saws and shears for simpler and more linear cuts;

- machining: after cutting, the workpieces are subjected to mechanical processing such as bending, punching and drilling. These operations require specific machinery and highly qualified operators;

- welding: using techniques such as continuous wire welding, TIG or MIG, the different pieces of metal are joined to form the final structure. Precision and quality of processing are essential to ensure the strength and durability of the material;

- finishing and surface treatments: once assembled, the product is subjected to finishing treatments to improve aesthetics and strength, such as powder coating, galvanisation and polishing;

- quality control: finally, strict controls are carried out to verify that the technical specifications and required quality and safety standards are met. This step is crucial to ensure that the final result is perfectly in line with the customer’s expectations.

The advantages of custom-made fabrication

Customization can bring significant benefits and advantages in terms of efficiency, safety and profitability for companies:

- optimisation of operational efficiency: each component is designed to fulfill a particular function, reducing waste and improving operability;

- versatility: the possibility of creating increasingly diverse creations that fit into existing structures;

- extending the life of components: through repair, reinforcement or upgrade, it is possible to ensure that they continue to perform their task efficiently for years.

If you are looking for a partner for your next project, make sure to choose a company that can combine careful design and the use of advanced technologies, and is able to meet high quality standards. Ferrero Industrial stands out in the field of custom-made metal carpentry thanks to a highly specialized design service, aimed at companies that need precision components.

If you are looking for a partner for your next project, make sure to choose a company that can combine careful design and the use of advanced technologies, and is able to meet high quality standards. Ferrero Industrial stands out in the field of custom-made metal carpentry thanks to a highly specialized design service, aimed at companies that need precision components.

In particular, the company offers customized solutions for the manufacture of components for drilling machines, components for aerial platforms and telehandler parts, ensuring products that can withstand extreme stress and operate in harsh environments. It is also able to supply industrial vehicles parts and car carrier trailer parts of different types, sizes and quantities, designing customized solutions that combine resistance, durability and high efficiency. Thanks to a team of experienced engineers and technicians, Ferrero Industrial is able to transform the specific needs of its customers into detailed projects, ensuring the high quality of the materials used and a careful control of each stage of the production process, meeting the highest standards in the industry.

For more information, or if you are interested in a consultation about it, contact us!