Hot dip or cold galvanizing? Features and differences

Find out the difference between hot and cold galvanizing and how to choose the treatment that best suits your needs

Corrosion protection is an essential element in the design and production of metal components intended for use in outdoor environments or in particularly demanding operating conditions. The combined action of oxygen, humidity, salinity and chemical agents can in fact generate corrosive processes capable of progressively weakening the material, compromising its mechanical resistance, reliability and, in the most serious cases, structural safety. Preventing these phenomena not only means extending the useful life of components, but also containing maintenance costs, avoiding system downtime, and ensuring optimal and long-lasting performance.

Among the most effective solutions to counteract metal oxidation is galvanizing, a surface treatment that creates a protective barrier capable of isolating the material from external agents and, in the case of hot-dip galvanizing, also offering active cathodic protection. However, there are different ways of applying zinc, each with specific characteristics, yields and purposes. The two most common techniques are hot-dip galvanizing and cold-dip galvanizing, each indicated for specific technical and operational needs.

A clear understanding of the difference between hot or cold galvanizing is therefore essential to choose the most suitable treatment based on the type of component, environmental conditions and required strength. Let’s see together how hot and cold galvanizing works, the main differences between the two processes and the peculiar technical characteristics that make each method more suitable for certain applications.

What is hot-dip galvanizing and how it works

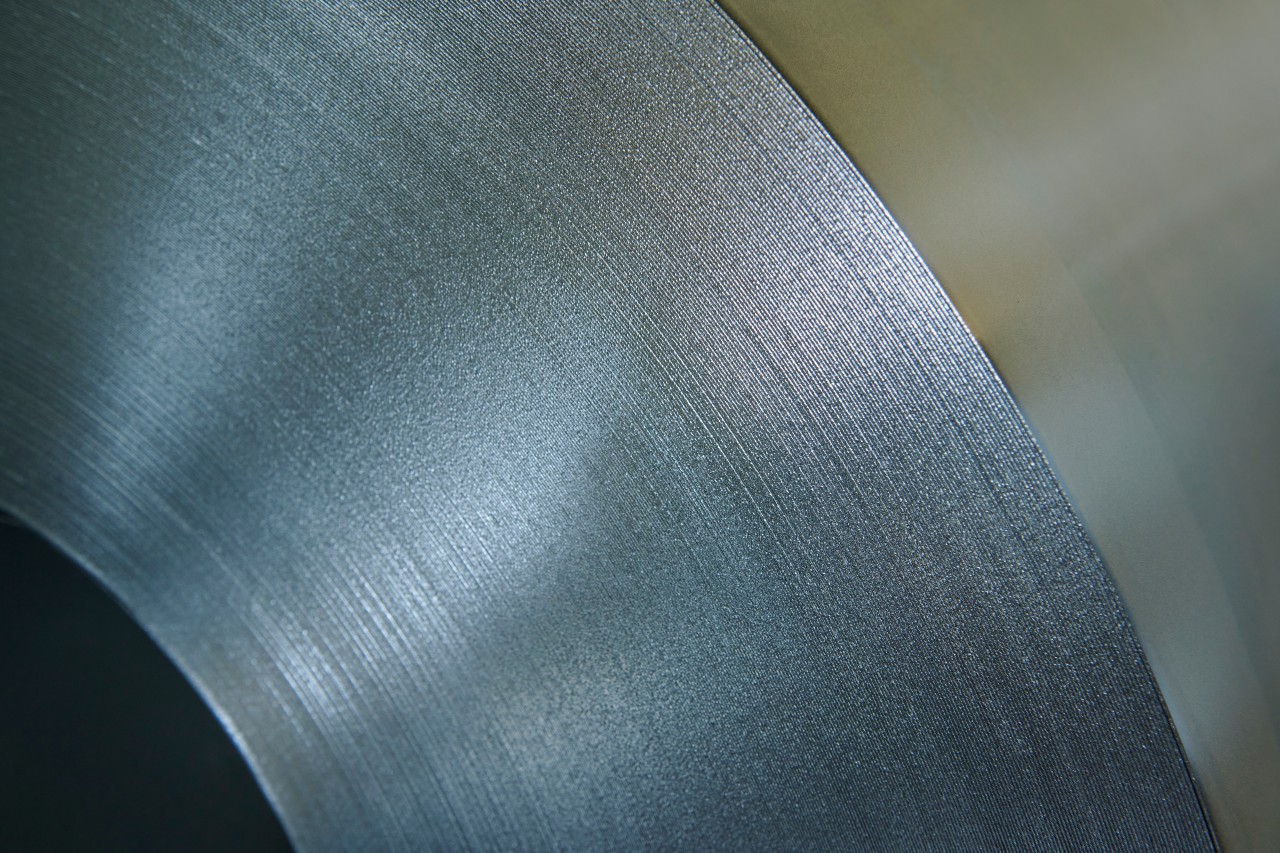

Hot-dip galvanizing is one of the most effective and long-lasting corrosion protection processes for metal products, especially steel. This is a heat and chemical treatment that involves immersing the component in a molten zinc bath at approximately 450 °C, thus creating a uniform, highly resistant coating that adheres perfectly to the substrate. This treatment is carried out in several stages to ensure maximum adhesion and protection. Specifically:

- degreasing and cleaning: the metal component is thoroughly cleaned to remove oils, paints, rust and other surface impurities;

pickling: the piece is immersed in acidic solutions to remove any residual oxidation and impurities from the metal surface, ensuring correct adhesion of the zinc; - fluxing: the product is treated with a specific solution (generally based on zinc and ammonium chloride), which further facilitates the bond between the metal and the zinc;

- immersion in molten zinc: the artifact is immersed in a tank containing molten zinc (at a temperature of approximately 450-460°C). At this stage, a chemical reaction occurs that generates a protective layer made of iron-zinc alloy, which is extremely strong and long-lasting.

- cooling: once removed from the tank, the workpiece is cooled, usually by exposure to air or immersion in water, completing the galvanizing process.

The result is effective and long-lasting protection: zinc adheres firmly to the metal, creating an alloy that is resistant to weathering and rust.

What is cold galvanizing and how it works

Cold galvanizing is an anticorrosive treatment that involves applying a zinc coating to the metal surface using zinc rich products, i.e. paints or sprays with a high zinc powder content (generally greater than 90%). Unlike hot-dip galvanizing, it does not involve immersing the workpiece in molten zinc: it is, in fact, a simpler and faster room-temperature process, ideal for small interventions, touch-ups, or components that cannot be subjected to high temperatures.

Here again, the process begins with proper preparation of the support, which must be perfectly clean and free of rust, grease, pre-existing paint or oxides; it is often necessary to resort to wire brushes or sandblasting to ensure a surface rough enough to promote product adhesion. Once the surface is prepared, the zinc compound is applied by brush, roller or spray, forming a uniform film which, after drying, creates a physical barrier against moisture and weathering. Although a true iron-zinc alloy does not develop as in the hot process, the high zinc content in the coating allows for some level of cathodic protection, helping to limit oxidation of the underlying metal.

The process is appreciated for its practicality, low cost, and the ability to perform localized work directly on site, but it offers a shorter lifespan than hot-dip galvanizing, making it more suitable for repairs, repainting, or components not exposed to particularly aggressive conditions.

The main differences between hot and cold galvanizing processes

The differences between hot and cold galvanizing emerge clearly from a comparison of their specific characteristics. Hot-dip galvanizing process, requiring specialized systems and high temperatures, entails a higher initial cost, but represents a long-term investment. The generated coating is significantly thicker, more uniform and with a smooth surface, capable of protecting the steel effectively even in the presence of scratches. The durability of anti-corrosion protection offered by hot-dip galvanizing is significantly longer than that of cold-dip galvanizing. Under normal or moderately aggressive environmental conditions, hot-dip galvanized coating can provide effective protection for over 25-40 years, requiring only sporadic maintenance checks and rarely restoration work. This longevity is mainly due to the significant thickness and robustness of the zinc-iron alloy which adheres perfectly to the metal.

In contrast, cold-dip galvanizing offers a more economical and easily applicable solution directly on site using zinc-rich paints or sprays. The coating obtained is thinner, with a shorter lifespan that generally varies between 1 and 5 years, based on environmental exposure. This technique requires more frequent maintenance, such as touch-ups and periodic applications of the protective layer, especially at scratches or areas subject to greater wear. It is mainly indicated for minor interventions and small repairs since it has an often irregular finish and frequently requires further painting to optimize the final appearance.

The choice between these two techniques depends mainly on the operating context, the durability and strength requirements, and the budget available for anticorrosive treatment.

The different applications of hot and cold galvanizing

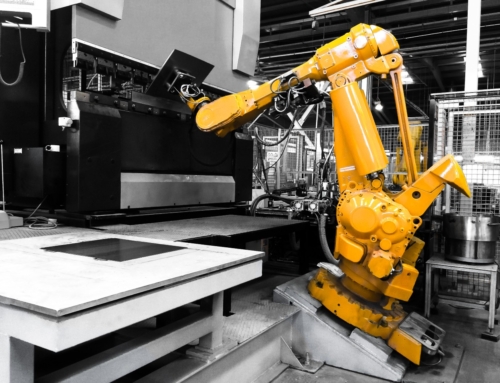

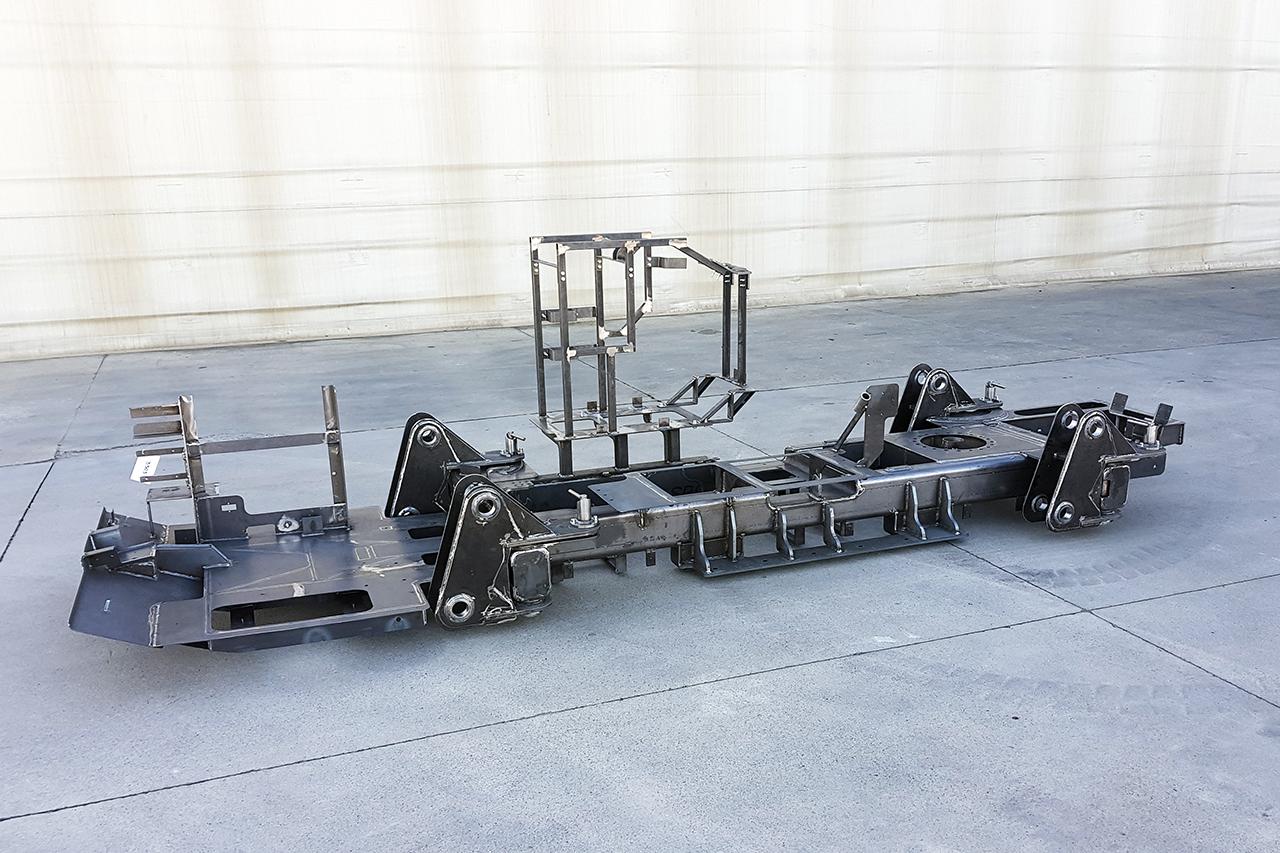

Hot-dip galvanizing is mainly used to protect metal structures that must ensure a long life, especially in hostile environments, characterized by marked corrosion and strong temperature variations. Due to its ability to offer exceptional and long-lasting resistance to corrosion, this process is widely preferred in numerous areas: from civil infrastructure to construction, from agriculture to livestock farming, from the industrial sector to transport.

As we have seen, on the other hand, cold galvanizing is particularly suitable for more rapid, localized or temporary interventions. It is in fact used mainly in ordinary and extraordinary maintenance operations, in the targeted protection of small surfaces and for temporary or intermediate applications. Although it provides lower anti-corrosion protection than hot-dip galvanizing, it stands out for its simplicity and speed of application. Precisely for this reason, it represents the ideal solution for the treatment of small metal parts, for applications in less aggressive environments and for the creation or restoration of artistic and decorative artefacts.

Surface treatments and galvanizing processes: the anti-corrosion solutions offered by Ferrero Industrial

Ferrero Industrial offers a full range of galvanizing processes and surface treatments designed to ensure effective, long-lasting protection for metal components, tailored to different application needs. Corrosion prevention is in fact a crucial element in ensuring reliability, safety and longevity of metal structures and high precision metal components. Thanks to the use of advanced technologies, we are able to respond to requests for anti-corrosion protection with tailor-made solutions, ranging from traditional galvanizing to the most versatile and practical treatments such as cold galvanizing. At the heart of the offering is a deep knowledge of coating materials and technologies, which allows you to precisely define the most suitable treatment for each application, optimizing costs, time and final results.

All surface treatments performed are characterized by a high level of control of all operational phases: from the preliminary evaluation of the piece to the application methods, up to the verification of the coating quality. This approach allows for uniform, stable finishes that maintain their protective properties even under particularly demanding conditions of use. We also pay particular attention to the adhesion of coatings and their ability to withstand mechanical, thermal and chemical stresses, thus ensuring a wide versatility of use.

The capacity to combine technical expertise, up-to-date technologies and high production flexibility makes Ferrero Industrial a reliable partner for all companies that need components with effective, long-lasting anti-corrosion treatments that are perfectly calibrated to their operational needs.

If you would like to receive more information or need personalised advice, please contact us!